Accurate Positioning of Embroidery on Clothing

2025-04-23Common Mistakes Made by Beginners in Embroidery

2025-05-09EMBROIDERY TIPS

How to Speed Up Embroidery Production - Tips for Increasing Efficienc

POSTED ON APRIL 29th, 2025 BY BAi

In the embroidery business, improving productivity is the key to scaling up and increasing profits. Embroidery is not only a classic art form, but also a business activity that requires precision and time management. As competition in the marketplace intensifies and customer demand increases, business owners and embroidery practitioners must find ways to speed up production to remain competitive and meet market demands. This article will detail several proven strategies to help you speed up embroidery production while maintaining high quality.

For embroidery machines

1、Maintain the machine regularly

Set the time for regular maintenance of the embroidery machine according to the frequency of embroidery. You can choose to do the maintenance at the end of a certain day's work. Please note that you should not start the embroidery work immediately after the maintenance because oil may drip down and dirty the white fabric during the operation. Regular maintenance of your machine will not only prolong its life, but also ensure high quality and consistency of embroidery.

2. Check the machine before embroidery

Before you start embroidering, be sure to carefully check the needles and bobbins of your embroidery machine. Sometimes, a slightly bent needle may be hard to notice during the embroidery process, but it will affect the embroidery effect, so you need to stop and check carefully. In addition, after a long period of embroidery, lint and thread flakes can accumulate at the bobbin, and these also need to be cleaned regularly to keep the machine clean to ensure the quality of the embroidery and the normal operation of the machine.

3. Upgrade your machine

The productivity of a single head embroidery machine is limited after all. A single head embroidery machine is a suitable option in the early stages of business, but as your embroidery business expands, upgrading your equipment is an inevitable step. Consider investing in a multi-head embroidery machine, which can significantly increase productivity and meet the demands of larger orders. Additionally, multi-head machines are more automated and can handle multiple colors and complex designs simultaneously, further enhancing production capacity and product quality. Upgrading your equipment will not only shorten production time, but also enhance your organization's market competitiveness and customer satisfaction.

Organize work area

Keeping your work area organized is essential to improving embroidery productivity. Arranging embroidery tools according to category can significantly reduce the time spent searching for tools during the embroidery process, thus increasing work efficiency. Once embroidery is complete, the workbench should be cleaned up and all used tools returned to their proper place in order to maintain a neat and tidy work environment. This not only helps to maintain an efficient workflow, but also extends the life of your tools and reduces the extra costs caused by damaged or lost tools. In addition, good work habits create a comfortable work environment that increases overall productivity and employee job satisfaction.

During the embroidery process, many auxiliary materials are required, such as embroidery threads and clothing white plates. To facilitate timely changes, these accessories should be prepared in advance in the work area to ensure that thread changes can be made quickly when they are needed. This reduces downtime and keeps the workflow consistent, thus increasing productivity.

When categorizing embroidery threads and frames, they should be arranged according to thread color and frame size. Sorting embroidery threads by color enables you to quickly find the color you need and improves work efficiency. Sorting and storing embroidery frames by size allows you to quickly select the right frame and avoid wasting time while the project is in progress. Additionally, clearly marking each storage area helps maintain organization over time. Keeping things neatly categorized not only improves workflow consistency, but also reduces errors and improves overall productivity and product quality. Regularly checking and organizing storage areas to ensure items are in their right place is also an important step in maintaining an efficient work environment.

Material Preparation

During the embroidery process, many accessories are used, such as stabilizers, bobbins and embroidery needles. Some of these accessories require you to cut and wind your own thread, which can be cost effective but time consuming. If you are pressed for time, consider purchasing pre-cut and pre-wound accessories, which, although slightly more expensive, can be a huge time saver and increase efficiency. In addition, the use of pre-treated auxiliaries also ensures quality consistency and reduces errors in operations, further improving the quality of finished products and production speed. Taking into account the cost of time and efficiency, choosing the right auxiliaries supply method can bring greater benefits to the embroidery business.

Utilizing embroidery time

While the machine is embroidering, you can use the time to prepare the next piece to be embroidered ahead of time or to clean up the last completed embroidery. Cleanup includes removing excess thread and stabilizer. This practice not only maximizes the use of time, but also ensures the quality of each embroidery piece. Additionally, advance preparation and timely cleanup helps to maintain continuity in the workflow, reducing wait times and increasing overall productivity.

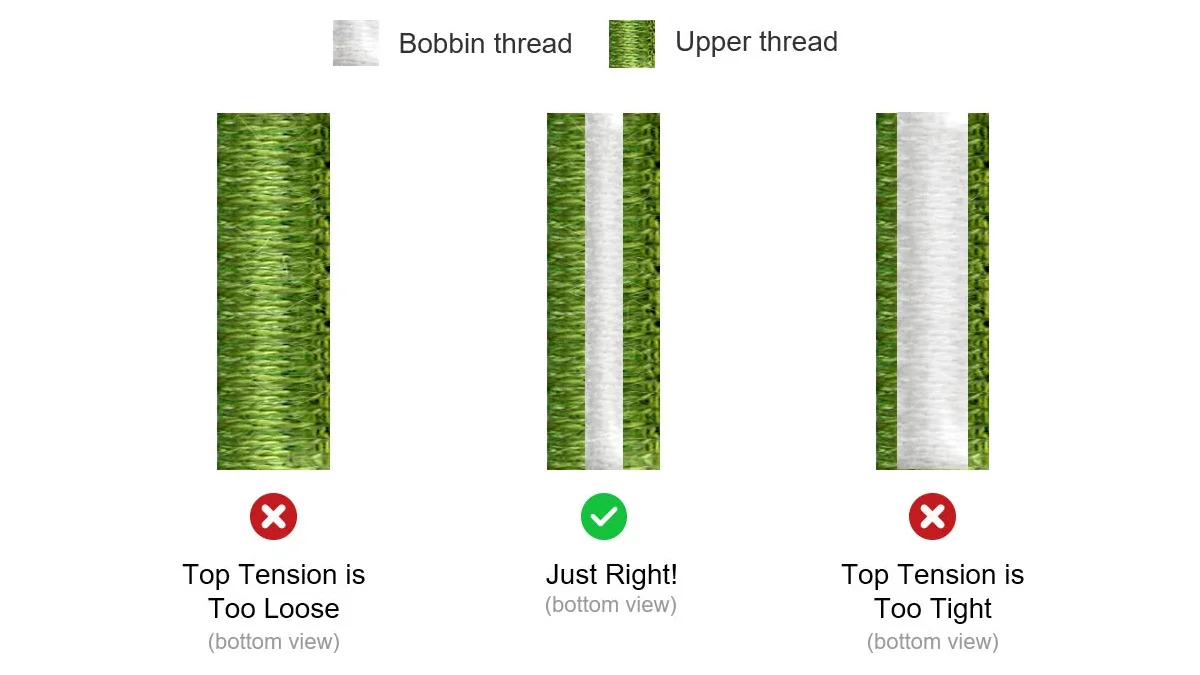

Test line tension in advance

Thread tension has a critical impact on embroidery quality during the embroidery process. Checking and adjusting thread tension in advance to ensure that the thread is not too tight or too loose when the machine is in operation can effectively minimize thread breakage and uneven stitching. Here are some specific measures to take:

1. Regular testing: Before starting a new embroidery project, conduct a thread tension test to ensure that the tension of each thread is within the proper range.

2. Use a tension meter: Use a professional tension meter to measure and adjust the tension of each thread to ensure consistency.

Optimizing designs and processes

Optimizing the design and embroidery process is a key part of improving productivity. By streamlining designs, optimizing embroidery paths and using efficient embroidery software, you can significantly increase efficiency and ensure that embroidery tasks are completed quickly while maintaining quality.

Simplified design

Choosing designs with fewer stitches and fewer color transitions will reduce embroidery time while maintaining the beauty and integrity of the design.

1. Reduced Stitch Count: Selecting designs with fewer stitches maintains the clarity and detail of the pattern while significantly reducing embroidery time. Avoid unnecessary complexity and excessive detail by rationally simplifying the design.

2. Color Optimization: Reduce the number of colors used in the design by using continuous colors and fewer color transitions as much as possible. This not only reduces thread change time, but also maintains the consistency and aesthetics of the design.

3. Design standardization: Create standardized design templates for common embroidery patterns to ensure fast and efficient embroidery work every time you use them.

Batch processing

Combining similar orders for processing will reduce the number of line and frame changes and increase production speed. The specific measures are as follows:

1. Order consolidation: Combining similar orders and processing them together reduces the time required for frequent thread and frame changes. This allows multiple similar embroidery tasks to be completed consecutively after a single clamping and setup, dramatically increasing production efficiency.

2. assembly line operation: implementing assembly line operation assigns different embroidery steps to different employees or machines so that each step can be carried out efficiently, reducing waiting time and overlapping operations.

3. Pre-preparation: During the embroidery process, while one machine is working, the materials and tools for the next batch to be embroidered are prepared in advance to ensure a seamless transition and maximize the use of time.

Improving embroidery productivity involves multifaceted optimization measures, from equipment maintenance, work area organization, material preparation, to design optimization, each of which requires careful management. By regularly maintaining machines, checking thread tension, optimizing the design process and scheduling working hours, you can significantly improve the productivity of your embroidery business to meet growing market demand. A combination of these strategies will not only improve productivity and product quality, but also enhance the company's market competitiveness and achieve greater business success.

-1.png)